- info@sparkgastechnologies.com

Skilled CGD professionals, PMC professionals, engineers, and semi-skilled technicians, plumbers, welders, electricians, fitters, operators and others will be needed in significant numbers if all the CGDs have to meet their committed targets. Thus, assuming a conservative estimate of 1,500 to 1,800 people per district engaged by the CGD entity means that overall, the CGD business has the potential to create between 5 lakh to 7 lakh direct jobs in the next five years. In addition, the ancillary industries for CGD could create semi-skilled and unskilled jobs, which could be two to three times more than this number.

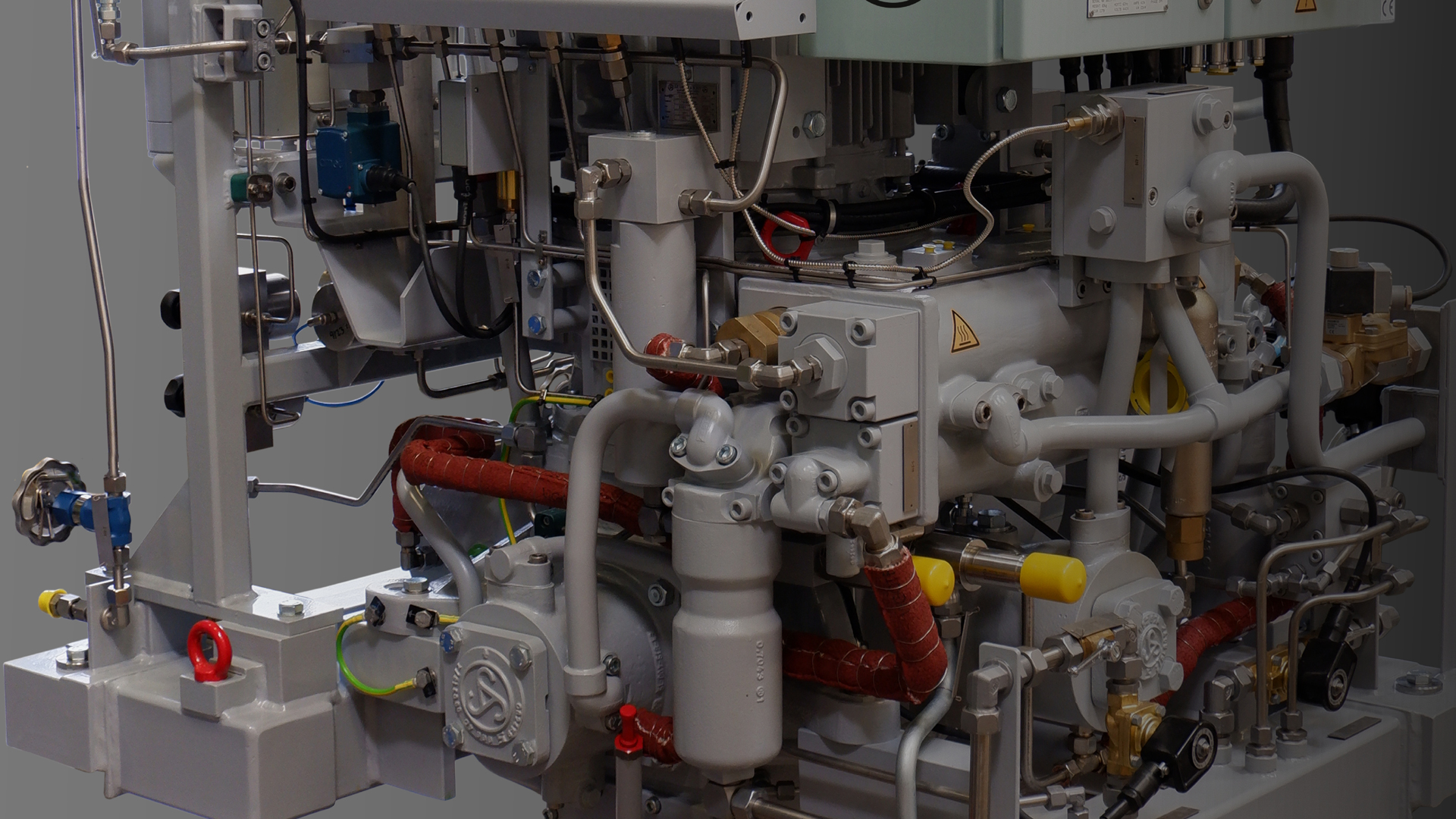

The ancillary industries needed to support the growth of CGD business can generate a significant number of additional jobs in the organized and unorganized sector. Take the case of compressors: Today the existing manufacturing capacity for compressors in India is between 300 to 350 per year and with only two to three companies manufacturing them locally. With the growth in CGD business expected over the next 5-10 years, the demand for compressors is likely to be three to four times the current production capacity. Similarly, the requirement of dispensers, cascades, meters, electrical, instrumentation, pipes, valves, cylinders etc, will increase significantly over the next few years.